TOP-DOWN CONSTRUCTION- ALL YOU NEED TO KNOW

In most common construction methods, buildings with underground parts are built by the bottom-up method where sub-structure and super-structure floors are constructed sequentially from the lowest level of basement to the top of the building. Though this conventional method, also called a bottom-up method, is simple in both design and construction, it is not feasible for the projects with limited construction time or with site constraints (size of location, legal issues, etc). The Top-down construction method is the solution to these problems.

Top-down is defined by the use of the permanent internal structure as the temporary propping to the retaining wall, cast in a top-down sequence. The higher-level slabs are cast before the lower-level slabs to act as horizontal frames for wall support as the excavation progresses.

The Top-down method is mainly used for two types of urban structures, tall buildings with deep basements and underground structures such as car parks, underpasses and subway stations. The method has been used for deep excavation projects where tieback or anchor installation was not feasible and soil movements had to be minimized. There is a possibility of saving the overall construction time.

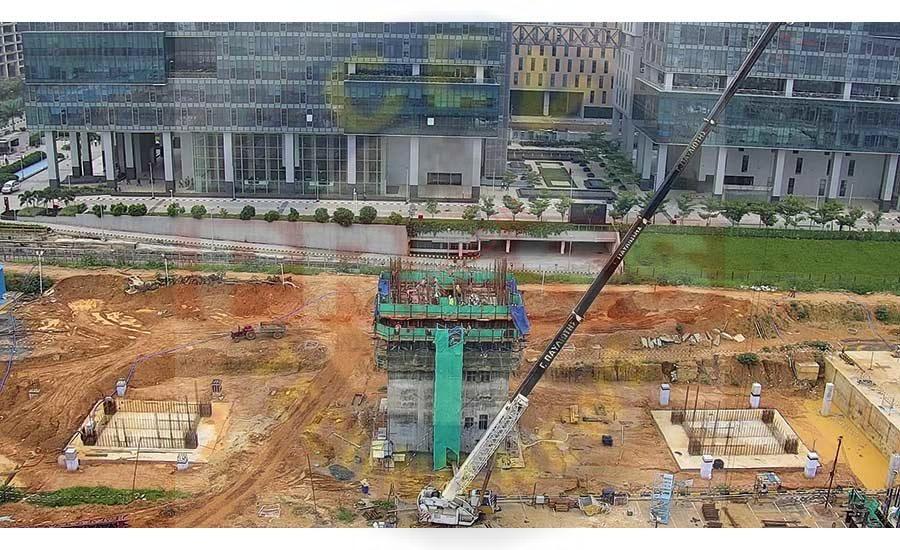

The construction begins with retaining wall installation and then load-bearing elements that will carry the future super-structure. The basement columns (typically steel beams) are constructed before any excavation takes place and rest on the load-bearing elements. These load-bearing elements are typically concrete piles or diaphragm wall panels

Construction Method

- Build up the perimeter wall and piles. The steel columns or stanchions should be arranged to that position where the piles are constructed.

- The floor slab should be cast for first basement level.

- Go into the first phase of excavation.

- The construction of the superstructure should be carried on.

- The floor slab should be cast for the second basement level. The second phase of excavation should be started.

- Reiterate the similar method unless the required depth is attained.

- Build up the foundation slab and ground beams, etc. Finish the basement.

- The construction of the superstructure should be continued unless it is completed.

Advantages

- The superstructure can be rebuilt beforehand prior to accomplishment of the building and the structures over the ground and it can be performed all together with the structures underneath the ground. It normally minimizes the construction time.

- Concrete diaphragm walls are more economical when they operate as a groundwater cut-off and temporary soil retention system at the same time throughout the excavation stage of the project, and then as permanent underground walls with load bearing strength for the finished structure.

- As it can be cast on prepared grade irrespective of applying bottom forms, the roof can be built up simply and cost-effectively.

- The structural slab operates as an internal bracing for providing the support for excavation, as a result the number of necessary tiebacks is minimized.

- The virtually vibration-free operation reduces the feasibility of ground movement and leads to detrimental settlement.

- Less width is necessary for construction area. Minimize ecological pollution connected with pre-construction earthworks.

- No need to underpin adjoining structures.

Disadvantages

- Due to the limits placed on the scale of the plant and the restricted access, the excavation works, and the building of the substructure must proceed at a more gradual pace and at a higher cost.

- It is impossible to install waterproofing on the outside surface of the walls.

- There is a possibility of water leaking out at the joints.

- To give access to future excavation, it may be necessary to leave holes in the slabs.

- The connections get increasingly difficult as you go down to the roofs, floors, and foundation slabs.

- Entry to the excavation is limited, and there is not enough room to build a foundation slab.

- In the temporary situation, the permanent slabs need some vertical support.

- Because of the construction’s increased rigidity throughout the intermediate phases, heavier loads could be accommodated by the permanent structure.

- The layout is complicated.