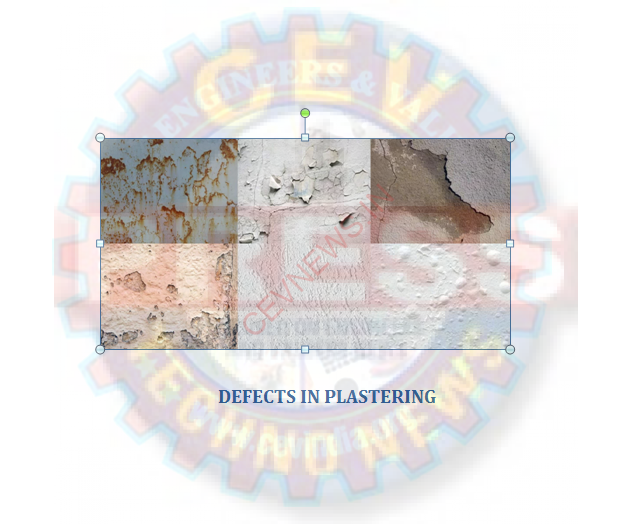

Several types of defects are found in plastering work which range from blistering, cracks, efflorescence, flaking, peeling, popping, softness and uneven surfaces. When these defects are visible, they should be repaired instantly.

- Blistering of Plastered Surface: Blistering of the plastered surface is happened when small patches are expanded outside the plane of the plastered surface. Blistering is visible for plastered surface inside the building.

- Cracks in Plastering: Cracks are developed on the plastered surface. Two types of cracks are found i.e. hairline cracks and wider cracks. The hairline cracks can?t be seen easily whereas the wider cracks are observed easily. The formation of fine cracks is termed as crazing.

Cracks on a plastered surface occur because of thermal movements, discontinuation of surface, structural defects in the building, defective workmanship, too much shrinkage etc.

- Efflorescence on Plastered Surface: Efflorescence is developed on plasters when soluble salts are found in plaster making materials and building materials like bricks, sand, cement etc. Even water applied in the construction work may include soluble salts.

When a wall (newly built up) dries out, the soluble salts are provided to the surface and they become visible in the form of a whitish crystalline substance. Such a growth is defined as efflorescence and the adhesion of paint with the wall surface is severely damaged with it.

Efflorescence provides a very ugly appearance and can be eliminated slightly through dry-bushing and washing the surface frequently.

- Flaking: The development of a very small loose mass on the plastered surface is called flaking and it is mainly occurs because of bond failure among consecutive coats of plaster.

- Peeling: In peeling, the plaster from some section of the surface are detached and a patch is developed. Peeling is primarily occurred because of bond failure among successive coats of plaster.

- Popping: Sometimes the plaster mix comprises of particles which get bigger on being set. A conical hole in plastered surface is created in front of the particle. This conical hole is termed as blow or pop.

- Irregular Plaster Surface: Irregular surface defect becomes apparent because of substandard workmanship of the plastering work.

- Softness of the Plaster: The extreme dampness at specific points on the plastered surface transforms that section soft. The softness mainly happens owing to unnecessary thinness of the finishing coats, existence of deliquescent salts, extreme suction of the undercoats etc.

- Rust Stains on Plastered Surface: Rust stains are sometimes visible on the plastered surface specifically when plaster is provided on metal lath.