COMPACTION FACTOR TEST- ALL YOU NEED TO KNOW

The compaction factor is defined as the ratio of the mass of compacted concrete in the compaction factor apparatus to the mass of fully compacted concrete. The compaction factor test is used for concrete which have low workability for which slump test is not suitable.

The compacting factor test is performed to ascertain the workability of the concrete. The slump test does not give accurate results for low worability of concrete when slump is<50mm.

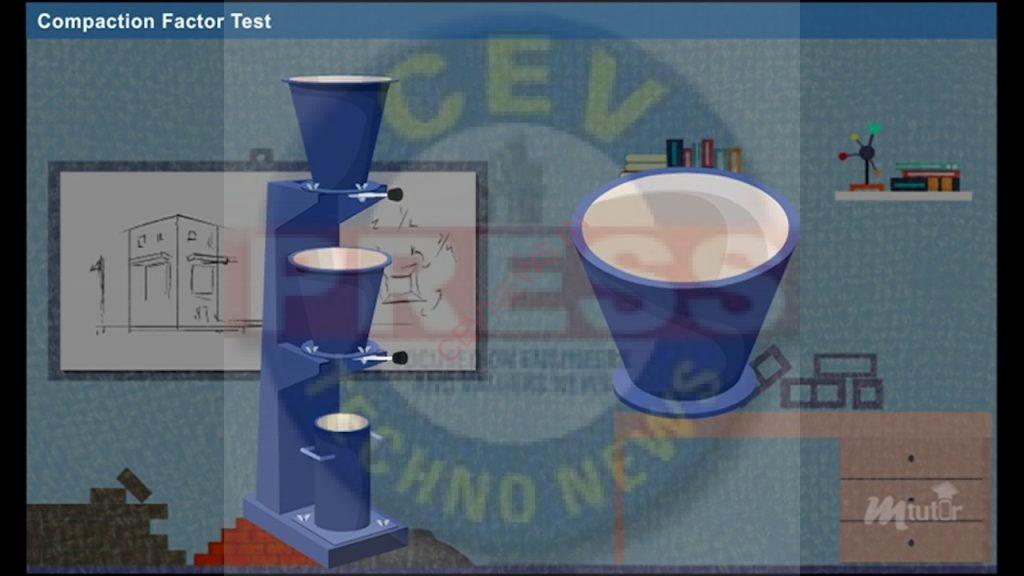

The compaction factor test is a workability test for concrete conducted in the laboratory. It was developed by the Road Research Laboratory in the United Kingdom and is used to determine the workability of concrete.

The compaction factor is defined as the ratio of the weight of partially compacted concrete to the weight of fully compacted concrete.

Procedure of Compaction Factor Test on Concrete:-

- Place the concrete sample gently in the upper hopper to its brim using the hand scoop and level it.

- Cover the cylinder.

- Open the trapdoor at the bottom of the upper hopper so that concrete fall into the lower hopper. Push the concrete sticking on its sides gently with the road.

- Open the trapdoor of the lower hopper and allow the concrete to fall into the cylinder below.

- Cut of the excess of concrete above the top level of cylinder using trowels and level it.

- Clean the outside of the cylinder.

- Weight the cylinder with concrete to the nearest 10 g. This weight is known as the weight of partially compacted concrete (W1).

- Empty the cylinder and then refill it with the same concrete mix in layers approximately 5 cm deep, each layer being heavily rammed to obtain full compaction.

- Level the top surface.

- Weigh the cylinder with fully compacted. This weight is known as the weight of fully compacted concrete (W2).

- Find the weight of empty cylinder (W).

Important: The test is sufficiently sensitive to enable difference in workability arising from the initial process in the hydration of cement to be measured. Each test, therefore should be carried out at a constant time interval after the mixing is completed, if strictly comparable results are to be obtained. Convenient time for releasing the concrete from the upper hopper has been found to be two minutes after the completion of mixing.

ADVANTAGES:

- Compression factor test gives more information than slump test.

- The test is a dynamic test and is thus more suitable for concrete mixture static tests.

DISADVANTAGES:

- The large and heavy nature of the device reduces its usefulness in the field. In addition, the test method requires an equilibrium to measure the mass of concrete in the cylinder.

- The amount of work applied to the concrete being tested is a function of friction between the concrete and the hopper, which probably does not reflect additional conditions.

- The test method does not use vibration, the main compaction method used in the field.

- This test is commercially available and is often used.

Calculation of Compaction Factor Value:

The compaction factor is defined as the ratio of the weight of partially compacted concrete to the weight of fully compacted concrete.

Compacting Factor = (weight of partially compacted concrete) / (weight of fully Concrete Concrete)

= W2 – W1 / W3 – W1

Here,

W1 = Weight of empty cylinder.

W2 = Weight of partially compacted concrete.

W3 = weight of fully Concrete Concrete.