3D SCANNING AND SURVEYING FOR REVERSE ENGINEERING

3D Scanning and Surveying for Reverse Engineering

Reverse engineering is a crucial process in various industries, allowing companies to deconstruct and analyze existing products or components to understand their design, functionality, and manufacturing processes. To efficiently carry out reverse engineering tasks, 3D scanning and surveying technologies have become indispensable tools. In this article, we will explore how 3D scanning and surveying play a pivotal role in reverse engineering processes, enabling businesses to innovate, improve, and stay competitive in their respective markets.

Understanding Reverse Engineering

Reverse engineering involves dissecting a product or component to gain insights into its design and functionality. This process is commonly employed in industries like aerospace, automotive, electronics, and more. The main objectives of reverse engineering are:

- Understanding Design: To comprehend the intricate design of a product or component, which may have been developed without available design documentation.

- Quality Improvement: Identifying areas for improvement, such as enhancing performance, durability, or manufacturability.

- Cost Reduction: Finding ways to optimize manufacturing processes, reduce costs, and eliminate inefficiencies.

- Interoperability: Ensuring that newly developed components or products can integrate seamlessly with existing systems or technologies.

Role of 3D Scanning in Reverse Engineering

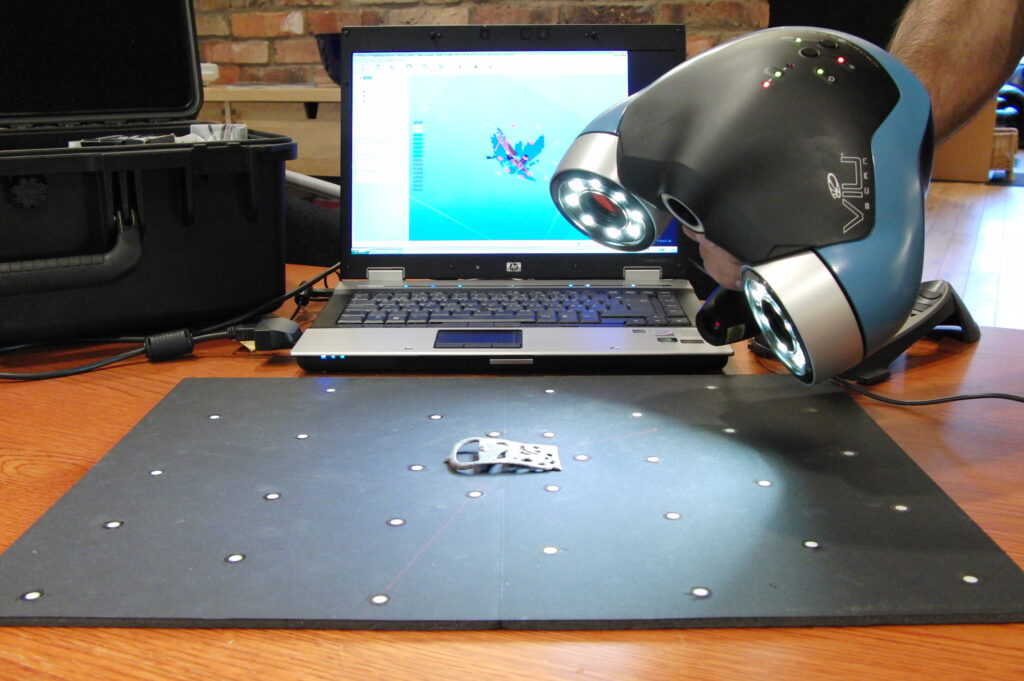

3D scanning is a technology that captures the geometry and surface information of physical objects, creating a detailed digital representation. Here’s how 3D scanning contributes to reverse engineering:

1. Accurate Data Capture

3D scanners can capture intricate details of objects, including complex shapes, curves, and fine textures. This level of accuracy is crucial when reverse engineering high-precision components.

2. Rapid Data Collection

Compared to traditional measurement methods, 3D scanning is significantly faster. It can capture thousands of data points per second, enabling quick and efficient data collection.

3. Non-destructive Process

3D scanning is non-invasive, meaning it doesn’t damage the original object. This is particularly important when dealing with valuable or irreplaceable items.

4. Data Visualization

The resulting 3D scan data provides a visual representation of the object, making it easier for engineers to understand its structure and components.

Surveying Techniques in Reverse Engineering

In addition to 3D scanning, surveying techniques are often used in reverse engineering, especially for large-scale objects or environments. These techniques include:

1. Laser Scanning

Laser scanning uses laser beams to measure distances to objects and create highly accurate point clouds. It is ideal for capturing large and complex structures.

2. Photogrammetry

Photogrammetry involves taking multiple photographs of an object from different angles and using software to reconstruct its 3D model. It is useful for objects that are challenging to reach with a scanner.

3. Structured Light Scanning

Structured light scanning projects a pattern of light onto an object and measures deformations in the pattern to create a 3D model. It is effective for capturing detailed surface information.

Challenges and Considerations

While 3D scanning and surveying are powerful tools for reverse engineering, there are some challenges and considerations to keep in mind:

1. Data Processing

Handling large volumes of 3D scan data requires robust processing capabilities and specialized software tools.

2. Material Properties

The material properties of the object being scanned can affect the quality of the scan. Reflective or transparent materials may pose challenges.

3. Cost

Investing in 3D scanning equipment and software can be expensive, but the benefits in terms of efficiency and accuracy often outweigh the initial costs.

3D scanning and surveying have revolutionized the field of reverse engineering. These technologies enable businesses to dissect and understand complex products, leading to improved designs, reduced costs, and increased competitiveness. As technology continues to advance, we can expect even more powerful and cost-effective solutions to emerge, further enhancing the capabilities of reverse engineering in various industries.