UNDERSTANDING THE WORKING PRINCIPLE OF HYDRAULIC MACHINERY

Hydraulic machinery plays a critical role in a variety of industries, including manufacturing, construction, and transportation. Understanding the working principle of hydraulic machinery is essential to their safe and efficient operation. In this article, we’ll explore the basic principles of hydraulic machinery and how they function.

Hydraulic machinery relies on the principle that fluids are incompressible, meaning that they cannot be compressed or reduced in volume. This principle is used to transfer energy from one point to another. Hydraulic systems use a fluid, typically oil or water, which is pressurized and then transmitted through a series of tubes or hoses to actuate machinery.

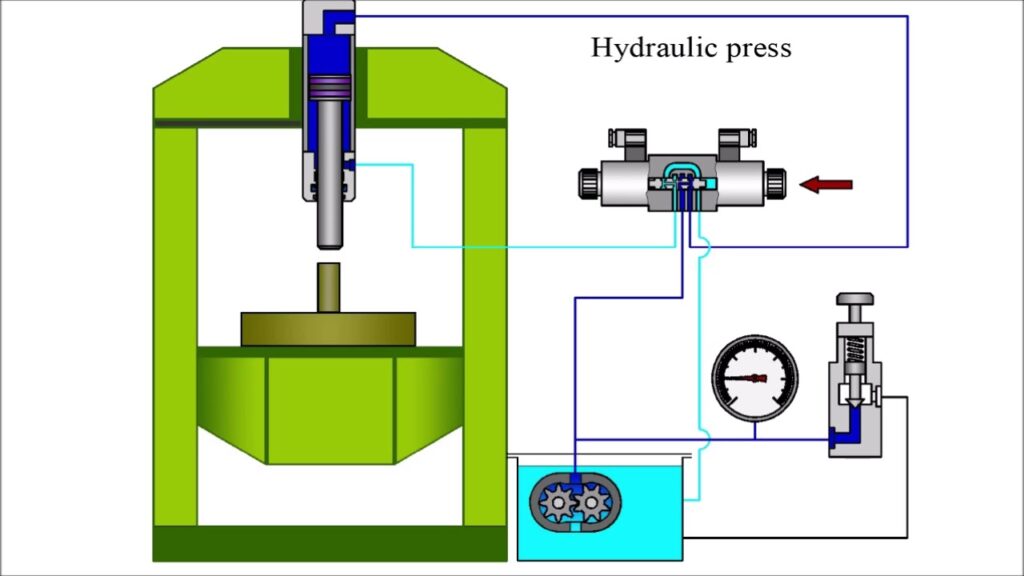

The basic components of a hydraulic system are a pump, valves, and actuators. The pump is responsible for generating the pressure required to move the fluid through the system. Valves are used to control the flow of the fluid and direct it to where it’s needed. Actuators are devices that convert hydraulic pressure into mechanical force and are responsible for performing the actual work.

The most common type of actuator used in hydraulic machinery is the hydraulic cylinder. A hydraulic cylinder consists of a piston and cylinder, with the piston able to move back and forth inside the cylinder. When hydraulic fluid is pumped into one side of the cylinder, it pushes the piston to the other side, generating mechanical force. The force generated by the hydraulic cylinder is proportional to the amount of pressure and the surface area of the piston.

Another common type of actuator used in hydraulic machinery is the hydraulic motor. A hydraulic motor consists of a rotating shaft, which is driven by hydraulic pressure. The motor is typically used to power machinery that needs continuous rotation, such as a conveyor belt.

Hydraulic machinery is capable of generating extremely high forces, making them ideal for heavy-duty applications. However, the high pressure and force generated by hydraulic machinery also make them potentially dangerous. Proper safety measures must be taken when working with hydraulic machinery, including regular maintenance and inspection, and training for operators.

In conclusion, hydraulic machinery works on the principle that fluids are incompressible, allowing them to transfer energy from one point to another. Hydraulic systems use a pump to generate pressure, valves to control the flow of the fluid, and actuators to convert hydraulic pressure into mechanical force. Proper understanding and maintenance of hydraulic machinery is crucial to their safe and efficient operation.

Here’s some point-wise breakdown of the working principle of hydraulic machinery:

- Hydraulic machinery works on the principle that fluids are incompressible, meaning they cannot be compressed or reduced in volume.

- Hydraulic systems use a fluid, typically oil or water, which is pressurized and then transmitted through a series of tubes or hoses to actuate machinery.

- The basic components of a hydraulic system are a pump, valves, and actuators.

- The pump is responsible for generating the pressure required to move the fluid through the system.

- Valves are used to control the flow of the fluid and direct it to where it’s needed.

- Actuators are devices that convert hydraulic pressure into mechanical force and are responsible for performing the actual work.

- The most common type of actuator used in hydraulic machinery is the hydraulic cylinder.

- A hydraulic cylinder consists of a piston and cylinder, with the piston able to move back and forth inside the cylinder.

- When hydraulic fluid is pumped into one side of the cylinder, it pushes the piston to the other side, generating mechanical force.

- The force generated by the hydraulic cylinder is proportional to the amount of pressure and the surface area of the piston.

- Another common type of actuator used in hydraulic machinery is the hydraulic motor.

- A hydraulic motor consists of a rotating shaft, which is driven by hydraulic pressure.

- The motor is typically used to power machinery that needs continuous rotation, such as a conveyor belt.

- Hydraulic machinery is capable of generating extremely high forces, making them ideal for heavy-duty applications.

- However, the high pressure and force generated by hydraulic machinery also make them potentially dangerous.

- Proper safety measures must be taken when working with hydraulic machinery, including regular maintenance and inspection, and training for operators.