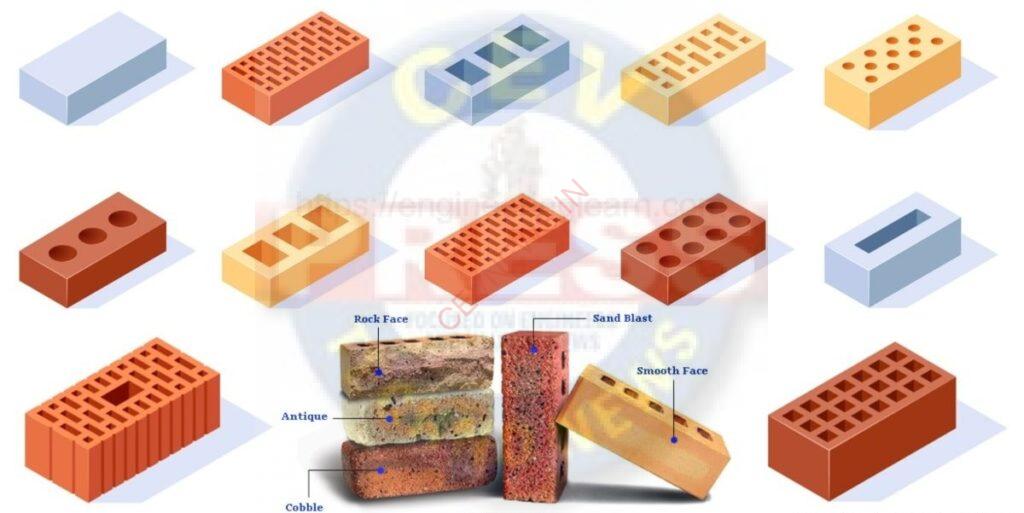

1. Perforated Bricks

Perforated bricks must not be confused with hollow bricks in the sense that perforated bricks have small diameter large number of holes or cavities. Perforated bricks give more compressive strength than the hollow bricks discussed below.

The perforated have perforations in cylindrical shape along their thickness. At the time of casting the bricks, iron tablets are pushed into the matrix of a brick to achieve a perforated material.

• The purpose to have these holes is to use the insulation properties.

• These bricks are much lighter in weight, easy to handle and thus ensure fast construction

• They can dry and burn quickly and easily.

• However, these bricks are never recommended for the hydraulic structure.

• Reduced usage of clay material.

The general dimensions of perforated bricks are 19×09×9 cm and 29×9×9 cm. Perforation area should not exceed 30 to 45% of the area of face.

2. Ordinary Bricks

Ordinary Bricks are solid rectangular blocks of standard shape and size with sharp edges and corners. These bricks are used as header or stretcher in a course and in ordinary projects they are only used for construction walls of 9 inches or 4.5 inches.

The nominal dimensions of the ordinary bricks are 225×112.5×75 mm (9”x4.5”x3”) but the architectural size or working dimensions or actual dimensions are 215 x 102.5 x 65 mm (8.5”x4”x2.5”). The ordinary bricks have different classes of quality and can be used both as load-bearing and non-load bearing walls.

3. Hollow bricks or Cavity bricks.

Volume of solid material in them should not be less than one-half of its gross overall volume. No web should be less than 1.5 cm thick (Fig. 2.12 and 2.13). Hollow bricks have the following advantages over ordinary bricks

i. These are only about one-third of the weight of the same size of ordinary bricks.

ii. These can be laid almost four times as fast as the ordinary bricks.

iii. These provide the advantages of hollow walls e.g. insulation against heat and sound.

iv. These are sufficiently strong for all purposes except for concentrated loads.

v. These are ideally suited for the construction of non-load bearing (partition) walls.

4. Cownose Bricks

Cownose brick is similar to bullnose brick with slight difference that in cow nose brick both the corners of the brick are moulded with rounded corners. It is also termed as double bullnose brick. The bullnose bricks are used at the edges where angular curved corners are recommended.

5. Channel Bricks or Gutter Bricks

These types of bricks are high strength glazed bricks used at the edges of a paved way or a hallway for the drainage purpose thus termed as drain bricks or gutter bricks. These bricks are moulded in the shape of channel like a drain.

6. Coping brick

These are of different shapes and sizes to suit various conditions of use. These are used as topmost course on parapets and their shapes are so made as to expeditiously drain off rain water from the top of parapets. When projecting the undersides of the projecting portions are provided with throats so as to throw the rain water off the faces of walls.

7. Paving bricks

Clay used for their manufacture contains more iron than the brick-earth used to manufacture ordinary bricks. Excessive iron causes the vitrification of bricks while burning. It gives them natural glaze as a result of which they can resist abrasion better.These bricks are mechanically shaped and not hand moulded. Their compressive strength is not to be less than 400 kg/cm2 and dimensions are 19.5×9.5×9 cm and 19.5×9.5×4 cm. these should not absorb water more than 5% of their weight on 24 hours of immersion in water.

8. Dogleg / Angle Bricks

The dog leg brick is a special shaped brick that is used to turn brickwork through an angle. It does not have a rectangular shape, the edges along the narrowest side forms an obtuse angle. These bricks are also termed as angle cut bricks.The use of dogleg brick enables to avoid the use of cut bricks and a mortar joint where the face of the wall changes direction.

9. Queen Closer

Queen closer is actually not a manufactured shape brick but is actually made by cutting along its length into two equal halves called queen closer. Queen closer is also termed as bonding bricks.

Queen closer is used to close up the bond at the end of the course. It prevents the joints of successive courses (higher or lower) to come in a vertical line.

10. King Closer

Like queen closer the purpose of king closer is the same, it is cut from the ordinary size bricks. The king closer is made by cutting the brick one half of its one dimension to the other half of its second dimension thus a triangular piece is removed which helps in making the corner course.